RFID ASSET TRACKING SOFTWARE & MANAGEMENT SYSTEM

Home | rfid-solutions | RFID Asset Tracking

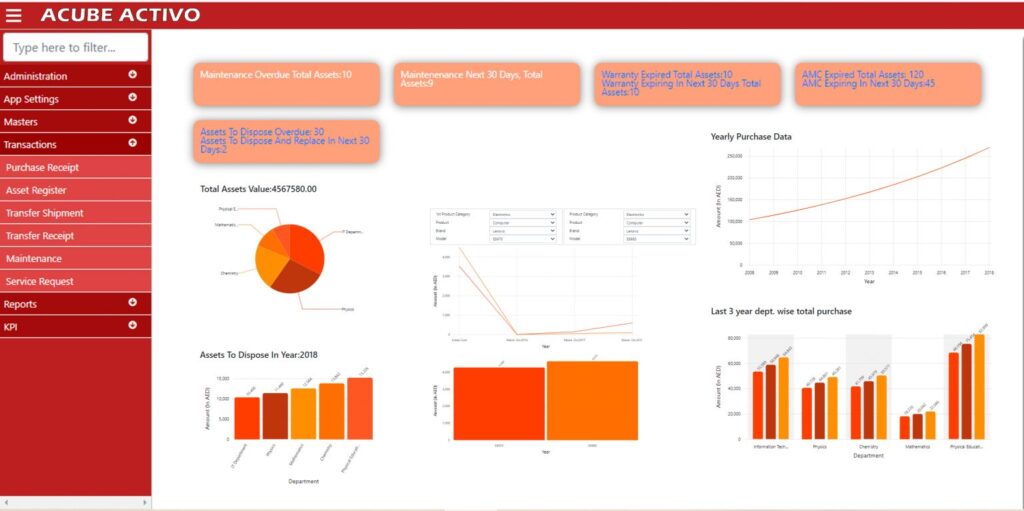

ACUBE ACTIVO RFID ASSET TRACKING SYSTEM

ACUBE is one of the leading RFID asset tagging solution providers, helping to simplify your company regardless of its size, type, or industry. It is critical to monitor asset status throughout its operational life cycle, as well as identify and spot assets effectively, by implementing ACUBE RFID asset tracking solutions. By connecting RFID asset monitoring devices to your network, you will have access to real-time updated information. Voice, biometric, and RFID automation can be integrated into current business applications or ERPs to improve company compliance, user safety, and asset tracking. Our offered cloud-based asset tracking system & fixed asset management tracking software are very helpful.

ACUBE offers EPC global UHF Class1 Gen2 hybrid passive asset tracking App to boost product visibility and traceability in the BAK facility.

RFID provides the key benefits in the following ways.

- Productivity:- Quick and precise data gathering by utilizing RFID handy reader and automated UHF RFID fixed reader accompanying RFID asset tags UAE

- Accuracy:- Easy integration with ERP helps in formulating reports by eliminating human error.

- Compliance:- Timely, accurate financial and management reporting.

- Accountability:- Impose individual liability on company assets.

BENEFITS AND FEATURES

Real-time control and regulation

Instant registration

Location

Alerts

Eliminate futile work

Mobility

Factual understanding of the situation

Record of Physical conditions

PRODUCTS USED

Revolutionizing Asset Management with RFID Technology: Benefits, History, and Implementation

RFID asset tracking is a novel approach to keeping tabs on business assets, including inventory, tools, and other equipment, using RFID readers and tags.

As the IoT has increased, organizations that rely heavily on their assets have found Radio-Frequency Identification (RFID) an essential tracking option. The capacity to connect real-world assets to data-collecting technology like asset management software Saudi Arabia has had revolutionary effects in fields as diverse as airline baggage tracking and retail store security.

Globally, the business sector has increasingly used enterprise asset management during the last two decades. It’s no surprise that the asset monitoring industry will be worth $36.3 billion by 2025, given the importance of businesses like manufacturing, logistics, retail, and healthcare.

The RFID asset management system from Acube Infotech has shown itself as a ‘go-to’ solution as businesses seek full management of their revenue-critical assets. Considering the benefits, such as reduced work time and real-time location tracking, it’s hardly surprising.

Briefly Explain RFID Asset Tracking.

In its simplest form, RFID asset monitoring is an approach to automate the tracking and administration of material possessions. Information is stored on an RFID tag and then affixed to the necessary asset for operation. Name, status, amount, and geographical coordinates might be included.

An RFID reader may access the information on a tag by picking up the tag’s intermittent radio waves. Eventually, it will be monitored and used in a high-tech asset-tracking system moving forward.

You can eliminate the high margin for mistakes introduced using pen and paper or Excel spreadsheets and fully automate your tracking and monitoring processes.

- Monitoring a wide variety of resources in real-time

- Taking away the need for humans

- In-situ data acquisition

- Recovering misplaced or lost items

- Increasing the reliability of stock counts

You’ll understand the need for asset tracking and careful inventory management if your hospital asset management relies on its high-value assets to generate revenue. Products, machinery, information technology devices, automobiles, and personnel are all fair game.

There are several options for streamlining asset tracking, but RFID is the only tracking technology that offers optimal efficiency at the lowest possible cost.

Brief History of RFID Location-Tracking

Radio-frequency identification has been used to track physical “things” for some time. In actuality, the first fully functional RFID tracking device was used by the Allies to keep tabs on and identify enemy aircraft during World War II.

After the first RFID tag was patented in 1973, IBM developed the first Ultra-High Frequency (UHF) reader in the 1990s. By 2004, the American retail giant Walmart had spent nearly $500 million on RIFD initiatives, and RFID technology had improved significantly.

The second group alerted all customer-centric, asset-rich enterprises to the benefits of RFID.

Why Should You Implement RFID to Monitor Your Assets?

Asset-heavy businesses are under growing pressure from their stakeholders and customers to establish effective asset monitoring systems. In asset management, the end aim is the same regardless of firm size, kind, or industry. There has to be a monitoring setup that:

RFID tracking has these primary benefits:

Using RFID, companies can automatically monitor the movement of goods between storage and transit locations.

Because the data collection process is automated, businesses may obtain accurate updates in real-time straight to an asset monitoring system. From here, asset managers may monitor the supply chain, maintain tabs on inventory, and identify costly operating delays.

This eliminates the need for time-consuming manual tracking methods like spreadsheets, saving time and workforce.

Provides a reasonable rate of return

Due to the low cost of the necessary hardware, an RFID asset tracking system is within reach of businesses of all sizes. Making cloud based asset management software accessible to small and medium-sized businesses (SMBs) and big organizations with several offices and warehouses.

An RFID based asset management system is dependable and cost-effective compared to other asset-monitoring options. Because of the cheap operational costs, businesses in the industrial, logistics, and retail sectors have seen a return on investment of up to 200%.

Keep in mind that the average price of a passive RFID tag is about $0.08. Furthermore, you no longer have to invest in an expensive device since most modern smartphones already have built-in RFID scanning capabilities. Plus, a plastic tag may be used several times before breaking.

Reduces the Risk of Loss and Theft of Assets by Using RTLS

The cost of replacing stolen, misplaced, or lost assets may significantly impact a company’s bottom line. This is the norm for enterprises that rely heavily on their assets; for example, the American car industry loses $1 billion a year due to theft on building sites and spends $750 million annually replacing lost reusable packaging.

To add insult to injury, in 2016 alone, inadequate location tracking led to the loss of twenty-four million bags.

Using many RFID readers and antennas, businesses may triangulate the exact position of their assets from asset tagging services like Acube Infotech. Generating highly accurate and timely geographic information.

By removing the need to manually find assets, barcode asset management software reduces replacement costs and saves time and money. The healthcare industry is a frontrunner in the asset monitoring market, which makes sense given the number of hours spent searching for equipment by nurses (on average, 6000 each month).